The global economy has reached unprecedented heights, with GDP now surpassing USD 94 trillion. To make this work for everyone, we must move away from a linear “take-make-waste” economy and toward a more circular one. The Circular Economy (CE) concept has gained widespread attention recently to address rising resource demand and the traditional consumption model. It is quickly becoming a top priority on the construction industry’s policy agenda.

With the rapid emergence and growth of the manufacturing sector and the country’s young population, India now has the responsibility to make mindful choices that will put it on a path toward a more circular economy. One is adopting a more sustainable and regenerative model of development. The circular economy can help the country reduce energy consumption and improve its environmental performance.

According to the International Energy Agency, to achieve the goal of net zero carbon emissions by 2050, the direct building CO2 emissions must decrease by 50% by 2030. For the complete picture, here is some data to ponder over.

Adopting a low-carbon path could be the first step for the construction industry to reduce its contribution to greenhouse gas emissions.

How the Construction Industry is transitioning to a circular economy:

The construction industry has started taking note of its responsibility towards nature. The introduction of various measures by governing bodies to implement green practices is one step in the direction.

Following are some circular economy strategies in use.

- Reusing excavated local earth to create Eco-Friendly building material

Digging for natural resources contributes to environmental pollution. In addition to being transported to distant regions, the waste from mining and construction sites additionally ends up in nearby mines and quarries. Inefficient activities such as transporting, digging, and dumping waste contribute to air pollution and carbon emissions.

Digging for natural resources contributes to environmental pollution. In addition to being transported to distant regions, the waste from mining and construction sites additionally ends up in nearby mines and quarries. Inefficient activities such as transporting, digging, and dumping waste contribute to air pollution and carbon emissions.

Several organizations, however, are reusing locally excavated earth as building materials. BC Materials, Spain is an autonomous research center that works with construction firms, architects, and transport companies to reclaim and reuse surplus mass. It is responsible for recycling the earth into various construction materials such as clay plasters, compressed earth blocks, and rammed earth which is supplied to trade contractors and building companies.

- Cradle to Cradle (C2C) approach adoption in construction

The concept of the cradle-to-cradle approach is a sustainable method in construction. The traditional way of digging for natural resources destroys habitats and wastes energy. On the other hand, through the C2C process, the natural resources are fed with construction materials that can endure the various life cycles of the earth. It is fascinating to see how many construction companies are now adopting this method.

Many companies are devoting all their energies to creating constriction materials by recycling agri-waste resulting in materials with zero or negative carbon footprints that are eco-friendly and circular. They make for great options for construction materials and can go a long way in reducing carbon emissions for the industry. Some leading examples in the market are Agribiopanels made from straw, Husk & Bagasse, CocoBoard® made from Coconut shells, Hempcrete made from Hemp waste, and Rice house that makes plaster from Paddy waste.

- Construction material reusability

Due to the increasing scarcity of resources, hard-to-recycle waste, and the climate emergencies threatening the world’s construction industry, various companies are developing innovative solutions. One is finding new ways to reuse, recycle, and repurpose construction materials. Some of these include marketplaces that allow construction waste of one organization to become the raw material of another construction project. One such initiative has been started by go.materialsmarketplace.org they today boast of several chapters in the United States – Austin, Michigan, Ohio, Tennessee, Ontario & Washington.

- Plastic upcycling

There is a variety of plastic waste that is generated during construction, making it a challenge for the industry to reuse or recycle it effectively.

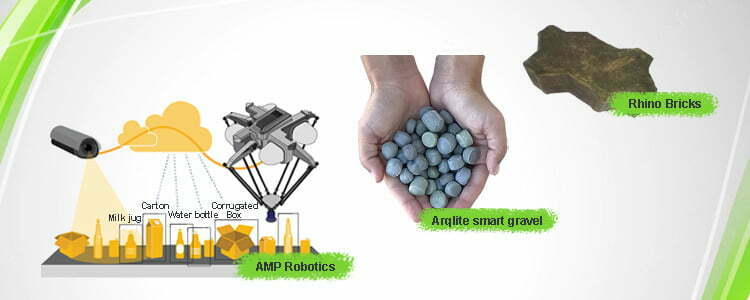

However, several companies are currently developing solutions to convert plastic waste into functional construction materials or convert unrecyclable plastic into recyclable plastic. For instance, Arqlite, a U.S.-based company, produces Smart Gravel, an insulating material from plastic packaging waste. Rhino Machine manufacturers in India are making bricks – Rhino bricks, made from foundry dust and waste plastic!

Some firms, such as AMP Robotics, are also developing robots that can automate the manual sorting of construction waste. These machines are helping minimize waste, whilst improving the efficiency of the process.

- Customisable modular units

As the global population increases, cities need to adopt new strategies to live more sustainably. One of the most effective ways to do this is by implementing smart modular construction. This type of construction allows contractors and customers to create prefabricated components and assemble them using traditional methods. It can reduce carbon footprint and waste and minimize water usage.

As the global population increases, cities need to adopt new strategies to live more sustainably. One of the most effective ways to do this is by implementing smart modular construction. This type of construction allows contractors and customers to create prefabricated components and assemble them using traditional methods. It can reduce carbon footprint and waste and minimize water usage.

Accelerating circular economy in the construction industry

To accelerate the adoption of the Circular economy in the Construction industry, there are some key players- organizations and Global certification agencies that identify and reward stalwart companies in the space. One such platform is PACE.

To accelerate the adoption of the Circular economy in the Construction industry, there are some key players- organizations and Global certification agencies that identify and reward stalwart companies in the space. One such platform is PACE.

PACE catalyzes global leadership from business, government, and civil society to accelerate the transition to a circular economy at a scale that can improve human and environmental well-being for current and future generations. This platform is led by an action-driven community of public and private leaders that are committed to circular change, providing leaders with the connections, learning, and opportunities to pilot and rapidly scale best practices that drive this change.

How does one measure and assess the circularity of a construction project?

While sustainability is a natural ask of a green building, it is advisable to start with a framework such as LEED, GRIHA, or BREEAM.

These are well-established tools that can help companies evaluate their current performance.

The green performance rating of a building is primarily measured on its natural/ecological concerns. Five key parameters that determine the green performance of a building are:

Early steps in transitioning towards a circular economy framework involve establishing certification and inspection procedures for various projects. Besides establishing efficient project procedures, process certification can also benefit companies that want to demonstrate their commitment to the circular economy.

However, the next step in the evolution of the circular economy is to develop a standard that includes all the necessary elements for the construction industry. According to experts, it will take a long time before the market can fully embrace the concept of circularity. However, the government and the private sectors must work together to stimulate the market’s move toward circular construction.

Conclusion

Like every other change, changing the complete thought process to a circular one is a big challenge for the construction industry. There is a lot on the drawing board and many initiatives to be kicked off, which will require significant investments to achieve the desired benefits. Education and awareness are other areas that will need work, supported by regulations and incentives to push down acceptance.

All said the circular journey has just started. We have miles to go before we sleep.